What is Precision Casting?

Precision casting, also called investment casting, is a lost wax casting process widely used for producing ferrous and nonferrous metal parts. Unlike other casting processes, precision casting produces net shape parts with excellent surface finish and dimensional accuracy. This manufacturing process is ideal for applications that have relatively low production quantities (100 to 10,000 pieces) or rapidly changing product designs.

Precision casting as a representative of the foundry industry in the field of high technology, the precision casting must play its exemplary role and take the lead.

But precision casting to play these two roles is the premise of a strong self, so China’s precision casting should be given priority to the development of up, development needs to established guidelines and development goals, the development of precision casting industry goals are the following.

First, from the rough and polluted to green intensive change, the quality, variety, and quantity of products and the world’s advanced level, the proportion of high-quality materials increased rapidly, the entire precision casting plant production efficiency, economic benefits multiplied; environmental pollution is effectively managed, the initial construction and environmental coordination of China’s foundry materials industry system.

Second, can continue to send professionals to enterprises, and constantly develop new varieties of high-quality, high-grade casting materials to meet the growing need for casting materials, while gradually increasing the efforts of technology exports.

Third, the elimination of a number of low technical levels, poor product quality, serious pollution, economic benefits of small precision casting plants, and the formation of a relative concentration of “small giant” and “star enterprises” to achieve “specialization, scale “production.

With precision casting, we can cast nearly 200 alloys. These metals range from ferrous—stainless steel, tool steel, carbon steel and ductile iron—to non-ferrous—aluminum, copper and brass. When cast in vacuum, super alloys are also available. The only process that matches this breadth of materials is machining, but it cannot produce the complex geometries that precision casting can deliver.

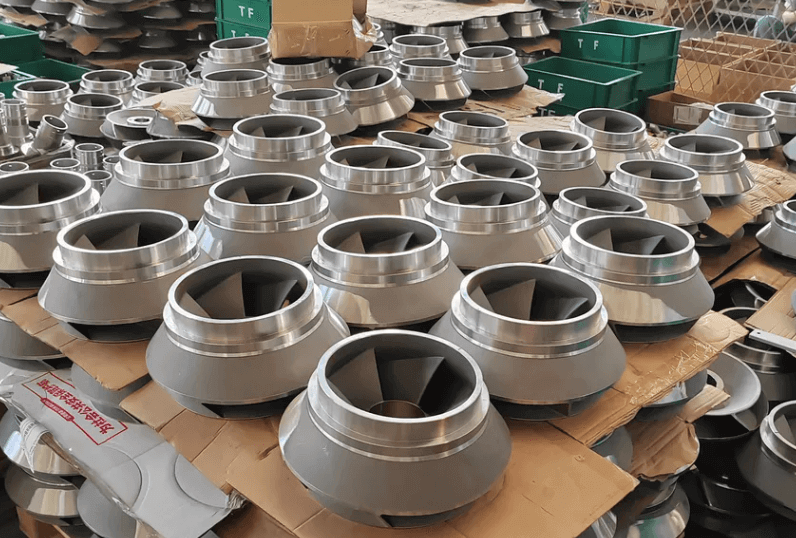

Since precision casting uses expendable patterns and ceramic shells, it is excellent for complex and detailed part designs. The process manufactures intricate parts that are difficult, if not impossible, to machine, forge or cast. Examples include internal passages and ports in a valve body, curved vanes of an impeller and internal cooling channels in a turbine blade. The critical barrier in prototype development and short-run production is the time and cost for injection molds. Each precision casting requires one wax pattern, and these patterns are injection molded. As design complexity rises, the tooling often becomes too costly and too time consuming to make prototyping and low-volume production practical.

In particular, to emerge one or two well-known enterprises in the world can compete with the backbone of the enterprise, their high level of technology, sophisticated technology, and equipment, strong capital, and advanced management level, can continue to provide the market with high-grade, high-quality casting material products, high market share.

If the precision casting industry can achieve the above development goals, and grow on its own, then the precision casting industry will be able to play its pioneering role in the foundry industry and leading role in driving the development of the foundry industry.

Precison Casting Process

PRECISION CASTING WAX INJECTION

The precision casting process begins with fabrication of a sacrificial pattern with the same basic geometrical shape as the intended finished cast part. Patterns are normally made of precision casting wax that is injected into a metal wax injection die (Fig. 1).

WAX PATTERN ASSEMBLY

WAX PATTERN ASSEMBLY

Fabricating the injection die can often require several months of lead time. Once a wax pattern is produced, it is assembled with other wax components on a central wax stick, called a sprue, to form a casting cluster or assembly (Fig. 2)

SHELL BUILDING

SHELL BUILDING

The entire wax assembly is then dipped in a ceramic slurry and covered with a sand stucco (Fig. 3), and allowed to dry.

DEWAXIN

DEWAXIN

The dipping and stuccoing process is repeated until a shell of 6-8 mm (1/4-3/8 in) is applied. Once the ceramic has dried, the entire assembly is placed in a steam autoclave to remove most of the wax and the remaining amount of wax that soaked into the ceramic shell is burned out in a furnace (Fig. 4)

CASTING & POURING

CASTING & POURING

At this point, all of the residual pattern and gating material is removed, and the ceramic mold remains. The mold is then preheated to a specific temperature and filled with molten metal, creating the metal casting (Fig. 5)

KNOCK OUT

KNOCK OUT

Once the casting has cooled sufficiently, the mold shell is chipped away from the casting (Fig. 6).

CUT OFF

CUT OFF

Next, the gates and runners are cut from the casting (Fig. 7).

FINISH

FINISH

After minor final postprocessing (sandblasting, machining), the castings – identical to the original wax patterns – are complete and ready for shipment (Fig. 8).

Manufacturing of Precision Castings

Precision castings are made in our lost wax investment casting method. The production process of precision castings includes injecting wax into patterns to form a wax model, building a tree assembling by sticking each wax model, creating a ceramic shell layer, pouring metal liquid into a sprue gate, and building a perfect shape like the wax pattern. Mostly, precision casting is the only solution for a newly designed parts for its high accuracy, free dimensions, smooth surface, and complex shapes. And the precision casting is economically manufactured for a low pattern cost.