In many regions, especially rural areas, well water serves as a crucial source of potable water and irrigation. To efficiently extract this groundwater, well water pumps are employed.

Understanding the parts that comprise these pumps, along with the manufacturing processes used to produce them, is essential for ensuring reliable operation and longevity.

This article will delve into the components of well water pumps, the significance of pump casting, the intricacies of investment casting, and the benefits of using stainless steel in pump parts.

Contents

Understanding Well Water Pumps

Well water pumps are designed to draw water from underground aquifers and deliver it to the surface for use in homes, irrigation systems, and industrial applications.

Various types of pumps can be employed depending on the depth of the well, the volume of water required, and the specific application. The two most common types of well water pumps are submersible pumps and jet pumps.

Types of Well Water Pumps

- Submersible Pumps:

- These pumps are placed underwater in the well and are designed to push water to the surface.

- They are highly efficient and can be used in deep wells where the water level is significantly below the surface.

- Submersible pumps are typically equipped with a hermetically sealed motor to protect against water intrusion.

- Jet Pumps:

- Jet pumps are located above ground and use suction to draw water up from the well.

- They are suitable for shallower wells and often require a foot valve to maintain water pressure.

- Jet pumps are versatile and can be used in various applications, but they may not be as efficient as submersible pumps in deeper wells.

Key Components of Well Water Pumps

Understanding the key parts of well water pumps helps in selecting the right pump for specific needs and knowing what to maintain or replace over time.

Here are the essential components of a typical well water pump:

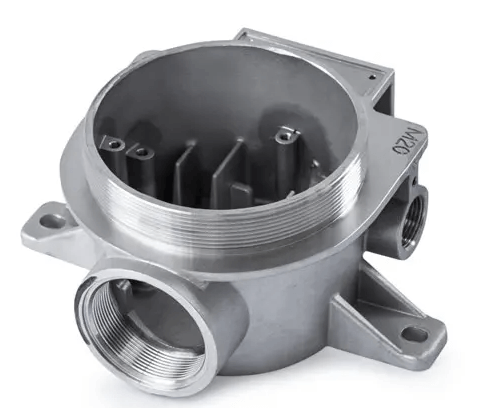

- Pump Housing:

- The outer shell of the pump that houses the motor and impeller.

- It is designed to withstand pressure and protect internal components.

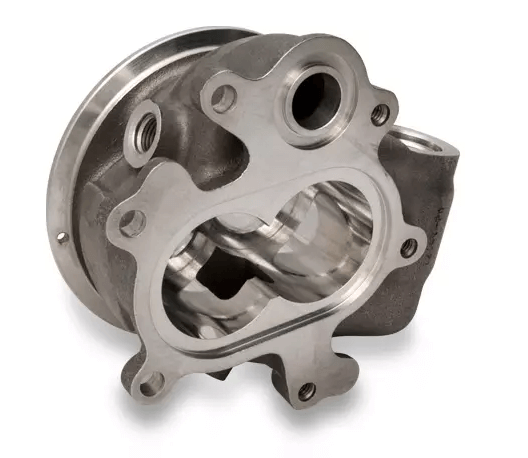

- Impeller:

- A rotating component that moves water through the pump.

- The design and material of the impeller play a crucial role in the pump’s efficiency.

- Motor:

- The driving force behind the pump, which can be either electric or powered by a combustion engine.

- The motor’s power rating determines the pump’s capacity to lift water from the well.

- Suction Strainer:

- A filter located at the intake of the pump that prevents debris from entering the system and clogging the pump.

- Discharge Port:

- The outlet through which water exits the pump.

- This component is often connected to plumbing systems for water distribution.

- Control Box:

- For electric pumps, the control box regulates the power supply and provides protection against overloads.

- Check Valve:

- A one-way valve that prevents water from flowing back into the well when the pump is turned off.

- This component helps maintain prime and ensures efficient operation.

Materials Used in Well Water Pump Parts

The materials selected for manufacturing well water pump parts are crucial for durability, efficiency, and resistance to corrosion and wear. Some of the common materials used include:

- Plastic: Lightweight and resistant to corrosion, plastic components are often used for low-pressure applications.

- Cast Iron: A traditional choice for pump housing, cast iron is strong and durable but may be prone to rust if not properly coated.

- Stainless Steel: An increasingly popular choice for pump parts due to its corrosion resistance, strength, and durability, making it ideal for long-term use in harsh environments.

Pump Casting

What is Pump Casting?

Pump casting is the manufacturing process in which molten metal is poured into a mold to create various pump components.

This method is critical in producing parts that require precision and durability, especially for well water pumps. There are several casting techniques used, each with its advantages and specific applications.

Types of Pump Casting Processes

- Sand Casting:

- A widely used technique where sand is utilized to create molds.

- This method is cost-effective for producing large parts but may not offer the precision required for intricate designs.

- Investment Casting:

- Also known as lost wax casting, this method provides high precision and is suitable for complex geometries.

- It involves creating a wax pattern that is coated in a ceramic shell. Once the shell is hardened, the wax is melted away, leaving a mold for pouring molten metal.

- Die Casting:

- This method uses high pressure to inject molten metal into a steel mold.

- It is often used for smaller parts due to its ability to produce parts quickly and with a smooth finish, though it is less common for larger pump components.

Advantages of Pump Casting

- Precision and Accuracy:

- Especially with investment casting, pump components can be produced with tight tolerances, ensuring a perfect fit for assembly.

- Material Versatility:

- A wide range of materials can be cast, including various metals and alloys suitable for pump manufacturing.

- Cost-Effectiveness:

- Casting methods, particularly sand casting, can reduce material waste and overall production costs, especially for large production runs.

- Complex Geometries:

- Investment casting allows for intricate designs that may be difficult or impossible to achieve with other manufacturing methods.

- Reduced Need for Machining:

- The casting process often produces parts that require minimal additional machining, reducing labor costs and lead times.

Investment Casting: A Closer Look

What is Investment Casting?

Investment casting is a sophisticated casting process that allows for the production of highly detailed and precise components.

It is particularly advantageous for manufacturing pump parts due to its ability to create complex geometries and smooth surface finishes.

It is particularly advantageous for manufacturing pump parts due to its ability to create complex geometries and smooth surface finishes.

The Investment Casting Process

The investment casting process consists of several critical steps:

- Pattern Creation:

- A wax pattern of the desired pump part is created. This pattern serves as a replica of the final product.

- Shell Building:

- The wax pattern is coated with a fine ceramic material to create a shell. This shell is heated to harden and form a durable mold.

- Wax Removal:

- The shell is heated further to melt and drain the wax, leaving a hollow mold ready for metal pouring.

- Metal Pouring:

- Molten metal is poured into the mold, filling it to create the desired pump part.

- Shell Removal:

- Once the metal has cooled and solidified, the ceramic shell is broken away, revealing the finished component.

- Finishing Processes:

- Additional processes, such as machining or polishing, may be performed to meet specific design and functionality requirements.

Benefits of Investment Casting for Pump Parts

- High Strength and Durability:

- Components produced through investment casting often exhibit superior strength compared to those made using other methods, thanks to controlled cooling processes.

- Exceptional Surface Finish:

- Investment casting typically provides a smoother surface finish, which reduces the need for extensive post-casting machining.

- Material Flexibility:

- Investment casting allows for the use of various materials, including stainless steel, making it suitable for producing corrosion-resistant pump parts.

- Cost-Effectiveness for Large Runs:

- While the initial investment in patterns may be higher, investment casting becomes cost-effective for larger production runs due to reduced waste and machining requirements.

- Reduced Lead Times:

- Investment casting can accelerate production schedules, which is crucial in industries requiring quick turnaround times.

Applications of Investment Casting in Well Water Pumps

Investment casting is particularly beneficial for manufacturing various components of well water pumps, including:

- Pump Housings: Designed to withstand high pressure and protect internal components.

- Impellers: Critical for moving water, impellers can be precisely shaped for optimal performance.

- Suction Strainers: Filters that prevent debris from entering the pump.

- Check Valves: Ensures one-way flow and maintains pump efficiency.

Stainless Steel in Pump Casting

Why Use Stainless Steel?

Stainless steel is a preferred material in the manufacturing of pump parts for several reasons:

- Corrosion Resistance:

- Stainless steel offers excellent resistance to corrosion, making it ideal for use in well water pumps that handle abrasive and corrosive materials.

- Strength and Durability:

- Stainless steel components are strong and can withstand the demanding conditions often encountered in water pumping applications.

- Temperature Resistance:

- Stainless steel can maintain its mechanical properties at elevated temperatures, making it suitable for various applications.

- Ease of Maintenance:

- Stainless steel components are easy to clean and maintain, contributing to the longevity of the pump.

Key Manufacturers of Stainless Steel Pump Parts Casting

Several manufacturers specialize in stainless steel casting for pump components, providing high-quality products that meet industry standards. Here are some notable manufacturers:

- Hengke Precision Metal:

- Specializing in investment casting for pump components, Hengke Metal offers high-quality stainless steel castings tailored to customer specifications.

- Dongying Arete Casting Company:

- Known for expertise in producing stainless steel pump parts through investment casting, Dongying Arete caters to various industries, ensuring high standards of quality and performance.

- Shandong Omicron Casting Co., Ltd.:

- This manufacturer provides a wide range of stainless steel casting solutions, including components for well water pumps, and is recognized for its commitment to quality and customer satisfaction.

Selecting the Right Pump Parts Manufacturer

Choosing the right manufacturer for well water pump parts and components is crucial for ensuring the reliability and longevity of the pump. Here are some key factors to consider when selecting a pump parts manufacturer:

- Experience and Expertise:

- Look for manufacturers with a proven track record in producing well water pump components and familiarity with industry standards.

- Quality Control:

- Ensure the manufacturer implements rigorous quality control processes to guarantee the performance and reliability of their products.

- Material Selection:

- Assess the manufacturer’s ability to provide a variety of materials, including stainless steel and other corrosion-resistant alloys.

- Customization Capabilities:

- If you require specific designs or dimensions, choose a manufacturer that offers customization options.

- Lead Times and Production Capacity:

- Evaluate the manufacturer’s ability to meet your production timelines and volume requirements. Short lead times can be critical in fast-paced industries.

- Customer Testimonials:

- Positive testimonials and case studies can provide insights into the manufacturer’s capabilities and reliability.

Environmental Sustainability in Pump Casting

Investment Casting and Sustainability

The casting industry is increasingly focusing on sustainability, and investment casting is no exception. Several factors contribute to the environmental friendliness of investment casting:

- Recycling of Materials:

- Investment casting often utilizes recycled metals, reducing the demand for virgin materials and minimizing environmental impact.

- Minimal Waste Production:

- The investment casting process generates less waste compared to traditional machining, contributing to a more sustainable manufacturing model.

- Inert Waste Disposal:

- The ceramic materials used in investment casting molds are classified as inert waste, allowing for easier disposal without environmental concerns.

- Energy Efficiency:

- Investment casting processes are designed to be energy-efficient, further reducing the carbon footprint associated with manufacturing.

- Responsible Material Sourcing:

- Many manufacturers are committed to sourcing materials responsibly, ensuring that they adhere to environmental regulations and standards.

Maintenance of Well Water Pumps

Importance of Regular Maintenance

Regular maintenance of well water pumps is essential to ensure optimal performance and longevity. Proper maintenance can prevent costly downtime and extend the lifespan of the pump components. Here are some key maintenance practices:

- Routine Inspections:

- Regular inspections should be conducted to identify any signs of wear or damage. Components such as seals, bearings, and impellers should be checked frequently.

- Lubrication:

- Moving parts, such as bearings, should be lubricated as per the manufacturer’s specifications to reduce friction and wear.

- Component Replacement:

- Worn or damaged components, such as impellers or liners, should be replaced promptly to maintain efficient operation.

- Cleaning:

- The pump should be kept clean to prevent debris accumulation that can hinder performance. Regular cleaning helps ensure optimal flow rates and reduces the risk of blockages.

- Monitoring Performance:

- Keeping track of the pump’s performance metrics, such as flow rates and pressure, can help detect issues early and prevent major failures.

Common Maintenance Challenges

- Wear and Tear:

- Slurry pumps are subjected to abrasive materials, leading to wear and tear on components over time. Selecting high-quality materials for replacement parts can mitigate this issue.

- Corrosion:

- Exposure to corrosive slurries can lead to corrosion of pump parts. Regular inspection and timely replacement of affected components are vital.

- Seal Failures:

- Pump seals can wear out, leading to leaks. Monitoring seal integrity and replacing them as needed is critical for preventing fluid loss.

Conclusion

Well water pumps are essential for extracting groundwater efficiently and reliably. Understanding the parts that comprise these pumps, as well as the manufacturing processes involved in creating durable and efficient components, is crucial for optimal performance. Pump casting and investment casting are significant processes in the manufacturing of pump parts, allowing for high precision, complex geometries, and material versatility.

Stainless steel is a preferred material for pump components due to its corrosion resistance, strength, and durability. Selecting a reliable pump parts manufacturer ensures that your pump components meet the highest standards of quality and performance.

As industries continue to evolve, the demand for efficient and durable well water pumps will remain paramount. Through continued advancements in manufacturing techniques and materials, the future of pump technology looks promising.

FAQ

- What are well water pump parts?

- Well water pump parts include various components, such as the pump housing, impeller, motor, suction strainer, and discharge port, that work together to extract water from a well.

- What is pump casting?

- Pump casting is the manufacturing process of creating pump components by pouring molten metal into molds.

- What is investment casting?

- Investment casting, or lost wax casting, is a manufacturing process that uses a wax pattern to create molds for producing intricate and precise metal parts.

- Why is stainless steel used in pump parts?

- Stainless steel is corrosion-resistant, durable, and suitable for handling abrasive and corrosive materials, making it ideal for pump applications.

- Who are the leading manufacturers of stainless steel pump parts casting?

- Reputable manufacturers include Hengke Precision Metal, Dongying Arete Casting Company, and Shandong Omicron Casting Co., Ltd.

- What are the benefits of investment casting for pump parts?

- Investment casting offers high strength, exceptional surface finish, material flexibility, cost-effectiveness for large runs, and reduced lead times.

- How often should well water pumps be maintained?

- Regular inspections should be conducted, with maintenance performed as needed to prevent costly downtime and extend the lifespan of the pump.

- What materials are commonly used for well water pump components?

- Common materials include plastic, cast iron, and stainless steel, each chosen based on the specific application and environmental conditions.

- What maintenance challenges do well water pumps face?

- Common challenges include wear and tear, corrosion, and seal failures, which can impact the efficiency and longevity of the pump.

- How does investment casting contribute to sustainability?

- Investment casting primarily uses recycled materials, produces minimal hazardous waste, and is designed to be energy-efficient, reducing the carbon footprint of manufacturing.