Contents

The Complete Guide: Valve Casting Parts

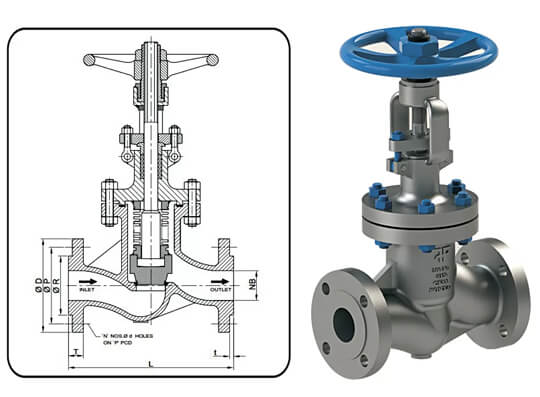

A valve is an integral part of a piping system that helps start, stop, reduce or increase, and control the flow direction. Moreover, it helps regulate the flow and the pressure of liquids, gases, slurry fluids, and vapor that flow through the pipes.

There are different types of valve made by using casting techniques. These valves find their use both in industrial and home settings.

These are cast valve components for

- Check valves,

- Control valves

- Plug valves

- Ball valves

- Globe valves

- Butterfly valve

The above valves may require different valve casting parts for replacement and repairs. Therefore, when designing the casting valve parts, several valve casting processes need to be used to produce the best versatile casting part to withstand pressure for a long time.

Therefore, the notable valve casting process used includes:

- The lost wax casting technique.

- Lost form casting method.

- Sand casting method.

- Investment casting process.

Again, the durability of a valve casting part will depend on several factors: the casting technique, the casting material, the valve casting parts dimensions, and the valve kind.

Moreover, the material used by the valve casting manufacturers to produce the best valve casting parts in the market are:

- Carbon steel.

- Gray iron,

- Ductile iron

- Stainless steel

When used with the best casting technique, the above material produces valve components with smooth surfaces with the best dimensions and tolerance. These valve casting parts include

- Cast valve body

- Cast valve bonnet

- Cast valve flange

- Cast valve disks and seats

- Valve trim

- Valve stem

Valve Casting Body Part

The valve body is a frame/outer shell that holds and keeps all other casting parts together. Therefore it is a pressure boundary that resists pressure from fluids, gases, and slurries from spilling outside. Besides, it is a valve casting part that connects the inlet pipe to the outlet port of the piping system.

When casting the valve frame, valve casting manufacturers use different valve body casting processes to have a valve body that fits its purpose, dimension, and material.

Besides, the valve body is a significant valve component that weighs up to 2 tonnes. Therefore the best-cast iron valve body process to use is sand casting. Moreover, the suitable material for this part is carbon steel, grey iron, and ductile iron.

Valve Casting Bonnet Part

The valve bonnet is a casting part that covers the top opening part of the valve body. Once you have installed all other internal casted valve parts inside the valve frame, the valve bonnet is attached to hold all the pieces together.

However, to hold the valve casting body part firmly with the valve bonnet, threads, bolts, and welded joints are used to secure these parts together. It is a high-pressure component that requires the valve casting manufacturers to use the best valve casting process. The best technique suitable for designing the valve bonnet is investment casting.

Where more machining and smooth surface finish is in focus, investment casting is the best casting technique. Moreover, the best investment casting material for casting the valve bonnet is stainless steel valve casting and grey iron casting.

Valve casting Disk and Seal ring

Valve Disk

It is a valve casting part located inside the body valve that opens and closes to allow and stops the flow of liquids, gases, and slurries in the tube. Moreover, depending on the valves’ type, the valve disk is referred to as the ball or the plug.

Usually, the valve disk is made from inert materials such as stainless steel, and they require precision and a smooth surface finish. Therefore, this valve component’s best valve casting process is lost form the casting technique and investment casting process.

Seal Ring/Toric Joint (Seat)

It is a valve component found inside the valve body. Therefore, an O-shaped joint is fitted with a gasket to allow the valve disk to interlock with it to stop a flow.

However, besides using the valve casting process, valve casting manufacturers use the forging technique to design the seal ring.

What is Valve Casting?

This is a process that makes valves using any form of liquid metal. That means valve casting manufacturers use molten liquid of different metals, which is poured into various molds, depending on the types, shapes, and dimensions.

Once the melted liquid in the molds cools and solidifies, you eject the intended valve by destroying the molds.

It is a process that is cost-effective when it comes to tools and machining, saves time, and requires a low workforce. Moreover, it allows valve casting manufacturers to produce valve castings of different shapes with complicated shapes and parts, using a diverse valve casting process.

Are valves Forged or Cast?

Yes, you can use both methods to make valves.

Valve casting manufacturers use both methods when making valves. However, some factors determine whether a valve is to be cast or forged. If the valve requires an intricate design with a perfectly smooth finish, then a valve made by using casting technique is the best choice compared to forged valves.

However, if you require a more superior valve that can withstand harsh conditions like high pressure and high temperatures, a forged valve will be an ideal choice. Although, a forged valve might not have a smooth and uniform look like those produced using the valve body casting process.

That does not mean that a forged valve does not have defects. Remember, both valves made from casting and forging undergo initial casting processes. Therefore they are exposed to the same flaws.

What is a Forged Steel Valve?

Valve casting manufacturers use the forging technique when making the steel valve. However, the conditions that produce these valves involve exposing steel metal to high temperatures and lots of thermal energy to produce high-grade steel valves that are strong, tough, and long-lasting.

Conclusion

We are professional casting manufactures that make all types of valve casting parts. Moreover, we supply finished components and types of valves made by using casting techniques. They range from large dimensions for industrial purposes and small sizes for domestic piping.

Visit us today to enjoy various types of valves and valve casting parts at a more manageable price.