Contents

The Complete Buying Guide: Heat Treatment Baskets

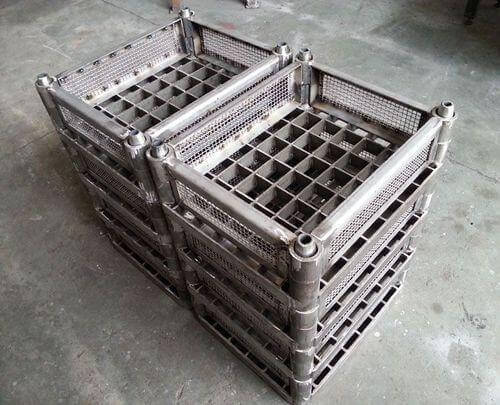

Furnace heat treatment parts like baskets and trays can be challenging to pick. First, you need to determine the right alloy and the optimal design that will deliver maximum performance and value over an extended period. Considering their costs, heat treatment baskets and trays require special consideration to ensure you get the right products and components in the market.

Alloys and designs tailored to meet your specifications and usage will help you improve throughput. In addition, an efficient process ensures more durable heat treatment baskets and trays with a longer lifespan at an affordable cost.

Heat Treatment Baskets, Fixtures, And Trays

Furnace parts like heat-treated baskets should be loaded properly. The heat treatment baskets or trays are usually loaded on grids or in the furnace hearth rails.

Currently, heat treatment baskets are mainly made of alloys such as stainless steel, graphite, or carbon composites. On the other hand, work grids are designed from high-temperature alloys. Therefore, it is very common to find graphite heat-treated baskets and plates in the market. However, buying these may mean insulating them to prevent eutectic melting.

It may require several heat treatment baskets, trays, and fixtures for a furnace to operate optimally. Due to the costs involved, maintaining heat treatment baskets should be a priority to minimize expenses.

Questions To Ask When Looking For the Right Heat Treatment Baskets

Buying the right heat treatment basket and other investment casting furnace components can be an overwhelming task. You should understand what you need and ask the right questions. You may want to weigh between upgrading an older fixture, buying a new one, and opting for a used part.

To find the right answers that guide you into making sound decisions, start with the heat treatment basket manufacturer or supplier. Then, understand the heat treatment process and various heat treatment components. Finally, here are questions that should help you find the right product in the market.

· How Hot Is The Heat Treatment Process?

The choice of material for heat treatment baskets and trays depends on the temperature of the process. If the heat treatment process is very hot, the heat treatment basket material should exhibit low creep, exceptional chemical and thermal stability, and excellent resistance to thermal fatigue.

Any heat treatment basket manufacturer must understand how to match the alloys and design to suit your applications. This helps you prevent cracking, creeping, and warpage.

· What Is The Atmosphere Around The Furnace Like?

Investment casting furnaces come in a wide range of types, designs, and atmospheres. Accordingly, they experience varying chemical and workflow processes. Therefore, in addition to compatibility with the heat treatment furnace components, you need to know what the atmosphere is like. This will help you determine the right heat treatment basket for the furnace.

Accordingly, the furnace atmosphere will help you determine the right material for investment casting trays and baskets. For instance, stainless steel heat treatment baskets can be very brittle, making them unsuitable for high-temperature processes. In its place, you may want to consider nickel and other high-temperature alloys.

· What Is The Size And Type Of The Furnace?

Heat treatment baskets, trays, and other fixtures are designed to be fitted in furnaces. Therefore, it is essential to keep in mind the size and type of the furnace you have before you opt for any component.

The furnace’s size, shape, and weight should help you determine the right heat treatment baskets to buy. Every component should fit into the furnace effortlessly for enhanced efficiency and overall performance.

· How Can You Maximize The Value?

A new heat treatment basket is likely to cost more than a used one. However, the initial cost should not always be a deciding factor when you want to buy any investment casting furnace part.

You may want to compare heat treatment basket prices to find parts that suit your budget. The most suitable approach is to look at the overall cost versus the output you get. This way, you should consider maintenance costs as well.

Other Considerations

· Durability

Special consideration should be afforded to the quality of the heat treatment basket. It is essential to buy a long-lasting component than opt for a more affordable option that will break down after a few months.

· Manufacturer

Before buying a heat treatment basket or any other investment casting furnace components, it is essential to look at the manufacturer’s portfolio. First, find out if the manufacturer is reputable enough. You may want to visit the investment casting company or foundry to understand the supplier’s processes.

· Uses

Where and how do you want to use the heat treatment basket? It is essential to evaluate your needs before going into the market.

· Your budget

Investment casting components come in a wide range of prices. Therefore, you should consider drawing your budget to determine the price point that sits well with your finances. Alternatively, you can look out for heat treatment baskets with a warranty. This helps you cover maintenance costs, reducing the overall cost.

· Delivery option

Heat treatment baskets are mainly manufactured in precision casting companies. Accordingly, the chances are that these foundries are not near you. In that case, you should find out from the supplier the delivery options available. For example, does the manufacturer offer free delivery?

Where to find the manufacturer

Heat treatment basket manufacturers in China remain the largest suppliers. However, you can also find investment casting companies near you. Whatever the case, this is a factor that you should always consider.

You can Google search and online directories to locate the best heat treatment basket suppliers in the market for a start. Referrals can also go a long way in helping you.

Summing Up

Buying heat treatment baskets represents a long-term investment that should be taken seriously. The process may also establish your relationship with a reputable heat treatment basket manufacturer. As much as it can be a daunting process for first-timers, it is always worth the effort, time, and money. For this reason, you should spend more time researching to ensure you get the best deal. If you do not know where to start, this article should point you in the right direction.