Foundries employ green sand casting as a molding method for shaping metals.

Despite its name, “green” doesn’t refer to the color of the material but rather to its uncured state when metal is poured into it.

The term originates from “greenwood,” signifying wood with high water content.

Green sand is a compound mixture primarily composed of sand, clay, sludge, anthracite, and water, with sand being the key ingredient. Green sand casting stands as a straightforward, dependable, and widely used technique in the world of metal casting.

It’s essential to differentiate green sand from “greensand,” a greenish sandstone not used in foundry applications.

The Green Sand Casting Process

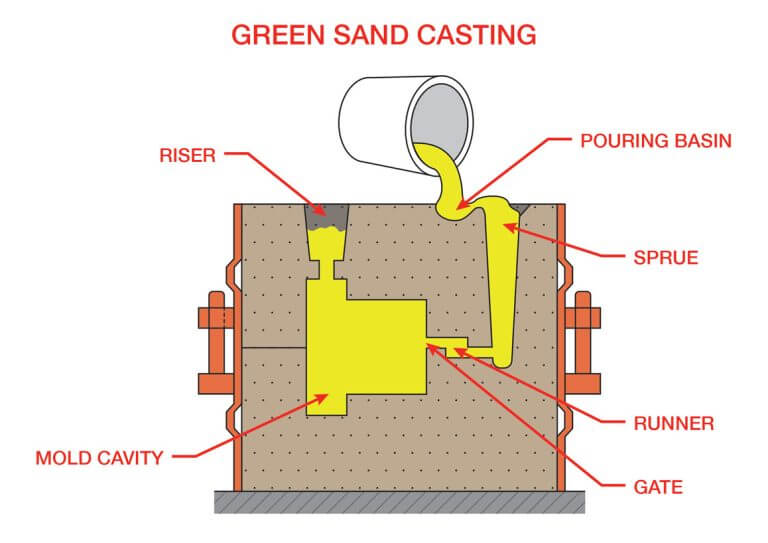

The process involves creating a mold by packing prepared sand around a pattern held within a flask.

Afterward, the patterns are removed, leaving behind the mold cavity into which molten metal will be poured.

Molds consist of two halves: the upper portion, known as the cope, and the lower portion, referred to as the drag.

The boundary dividing these halves is called the parting line.

Cores, formed from sand bonded with resins and hardened, are sometimes placed within the mold cavity to shape the internal structure of hollow castings.

Various chills can be embedded in the mold cavity wall to control the solidification process.

Risers act as reservoirs of molten metal, ensuring that all areas of the casting are properly fed until solidification is complete.

Additionally, they serve as heat sources, promoting directional solidification. Molten metal is introduced into the mold cavity through a sprue and distributed through a system of gates and runners.

What Constitutes Green Sand?

Green sand typically contains sand (comprising 75 to 85% by mass), bentonite or kaolinite clay (used as a binder, making up 5 to 11%), water (2 to 4%), sludge (3 to 5%, primarily acting as filler), and anthracite (less than 1%, added as a carbonaceous component).

The choice of sand type—silica-based, chromite-based, or zircon-based—depends on the casting material.

Other inorganic compounds may be incorporated based on the specific casting material.

Due to the high temperatures involved in metal casting, the ability to retain heat is crucial. Green sand’s porous nature is advantageous for mold production as it permits the escape of gases.

The Green Sand Casting Process in Six Steps

The green sand casting process can be broken down into six steps:

- Sand is placed over a pattern.

- A flask is used as a mold to shape the sand to the pattern.

- The pattern is removed.

- Molten metal is poured into the mold.

- The casting is allowed to cool and solidify.

- The finished casting is removed from the mold.

In this process, the latent heat from the molten metal cures the mold in place.

Molds are often ground down and reused, particularly if constructed using expensive sand types.

However, it’s worth noting that, on average, the US and UK landfill significant amounts of sand for every tonne of cast metal.

There have been successful efforts to recycle spent foundry sand for concrete production.

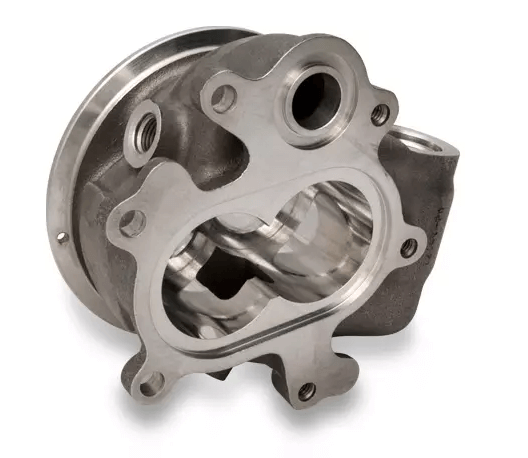

Green sand casting can be employed for a wide range of casting applications, from intricate small parts to large molds weighing up to 500 kg.

Advantages and Disadvantages of Green Sand Casting

Advantages:

- Simple production process compared to other methods.

- High production rates can be achieved.

- Low production costs due to inexpensive materials and a straightforward process.

Disadvantages:

- Common defects like sand residue, sand holes, air holes, and shrinkage.

- Tends to produce rough surfaces; using finer green sand is an option but increases costs.

- Limited size accuracy (size tolerance of CT11-CT12).

Hengke Metal Casting Solutions

Hengke Metal harnesses the efficiency and cost-effectiveness of green sand casting to manufacture a diverse array of products, including lampposts, counterweights, manhole covers, pump casings, trash bins, railings, gas burners, and more.

By collaborating with customers and utilizing optimal casting processes, Hengke Metal strives to deliver top-quality products while minimizing costs.