Die Casting vs. Foundry Casting & Investment Casting

In terms of the working mechanism, both investment casting and die casting seem to be similar. For instance, in both, molten wax is poured into a pre-designed mold or die. The most notable difference between dies casting and investment casting is how the molds are designed and the method of introducing molten metal.

During the die casting process, dies are made of tool-grade steel. On the other hand, this stage of mold making is a bit more complex during the investment casting process. Additionally, in die casting, molten metal is injected at high pressure and velocity, while in investment casting, molten metal is poured using gravity pouring.

This article will elaborate more on the differences and similarities between die casting, investment casting, and casting foundry.

Contents

What is the difference between investment casting and die casting?

There is a lot to look into if you want to figure out the difference between die casting and investment casting. In this section, your focus will be drawn onto factors worth considering when choosing either of the two casting processes.

The die casting process

The die casting process involved injecting molten metal into a hardened steel die cavities. The metal is later ejected from the die after solidifying. This process can be repeated severally to achieve the desired production volume.

The die casting process varies slightly, depending on the die casting material used. You can either opt for hot chamber die casting or cold chamber die casting.

The investment casting process

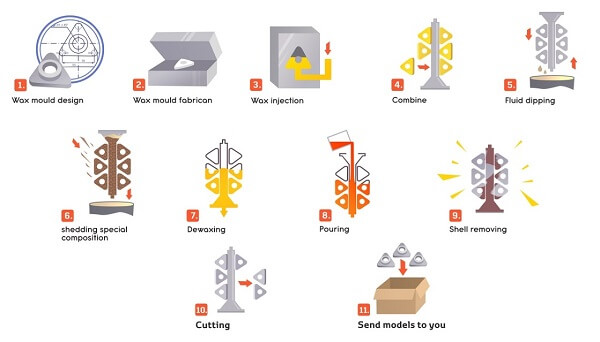

Producing components using the investment casting process is more time-consuming, requiring a wax prototype to be made and dipped in a ceramic slurry. Once the ceramic is hardened, it is preheated to melt away the wax. The molten metal is then poured using gravity, pouring into the mold then left to solidify before the mold is destroyed to get the finished part.

Molds used to create wax patterns can be reused for further production cycles.

Factors to consider when choosing between die casting and investment casting

Casting is an age-old metal fabrication technique. The basic casting process has not changed that much to date. However, the current era has seen an evolution in machines and technologies that power casting processes. Two of the most advanced casting methods die casting and investment casting, have wide applications in many industries today. But, how can you know the one that is suitable for your projects? Read on to find out.

· Material selection

Most die casting components are produced from non-ferrous metals and metal alloys. On the other hand, investment casting is capable of using a wide range of both ferrous and non-ferrous metals. Therefore, if you want a wide variety of material selections, investment casting is the process for you.

· Production volume

When choosing a casting process to use, you will want to consider your desired payback period. For instance, what volume is created versus the cost of tools used?

Investment casting is more cost-effective for low volume production, while die casting is ideal for larger production volumes.

· Tolerances

Tolerance capabilities are always a special consideration in the casting industry. You should compare general linear tolerance for both investment casting and die casting to find out the process that s suitable for your projects.

· Production cycle times

Investment casting and die casting are all excellent for producing complex parts. However, their cycle times differ significantly.

The investment casting process may require more labor and working hours. On the other hand, die casting can produce parts in minutes. Additionally, die casting can sometimes proceed to completion without any human labor involvement.

· Production cost

Production cycle times determine almost 60% of the overall production cost. In this case, investment casting will be more expensive than die casting.

When you need high production volumes, you should choose die casting. However, investment casting is ideal if you want to cast just a few parts.

What is the difference between die casting and casting foundry?

Over the years, casting manufacturers have used a combination of various metals to meet the desired specifications and metallurgical properties. Alloys have been created by mixing metal and non-metal components to increase material strength, toughness, durability, and surface hardness.

Currently, industrial casting materials are mainly iron and stainless steel. However, there is still the use of different alloys to achieve the desired outcomes. Carbon steel casting has enabled the creation of parts using carbon-enhanced compounds for specific properties.

However, one thing is not yet very clear. Most people ask about the difference between casting foundry and die casting. It is no surprise that this is a recurring topic of discussion whenever casting is brought up. However, the answer is very straightforward.

Casting foundries are factories or companies that offer casting services. For instance, your investment casting manufacturer or die casting manufacturer produces various components in the casting foundry. The term casting can be used as the process of metal fabrication or the final part produced in casting foundries. All the tools, techniques, and processes used to make castings are found under the roof of a foundry.

On the other hand, die casting is one of the casting processes you can use to produce metal parts. You are able to access various die casting parts because the manufacturer puts efforts into the foundry to make them using dies and molds to shape the desired product.

The die casting process has been discussed in other sections of this article.

The bottom line

Metal casting is one of the oldest techniques used to make products. Over the years, it has undergone massive evolution, owing to advanced technologies and a wide range of material selection.

The process can be subdivided into different techniques, such as sand casting, die casting, centrifugal casting, investment casting, and permanent casting. All these casting processes have advantages and disadvantages that make them suitable for different applications.

While investment casting and die casting are both excellent for producing complex products with comparable features. There are significant differences between the two processes that may prompt you to choose one at the expense of the other. The differences between investment casting and die casting are mainly found in the production process. Therefore, you have to evaluate and compare the two methods before settling on either for your casting needs.