Our Stainless Steel Investment Casting Process

1. Wax Model Making & Assembly

Once the mold is ready, inject wax material into the mold cavity, then take out the wax model from the mold after cooling. Repair some appearance defects of wax models, such as slot, wax injection nozzle, flow pattern, etc. After inspection wax models, weld them to the casting system one by one to form a assembly, which looks like a tree.

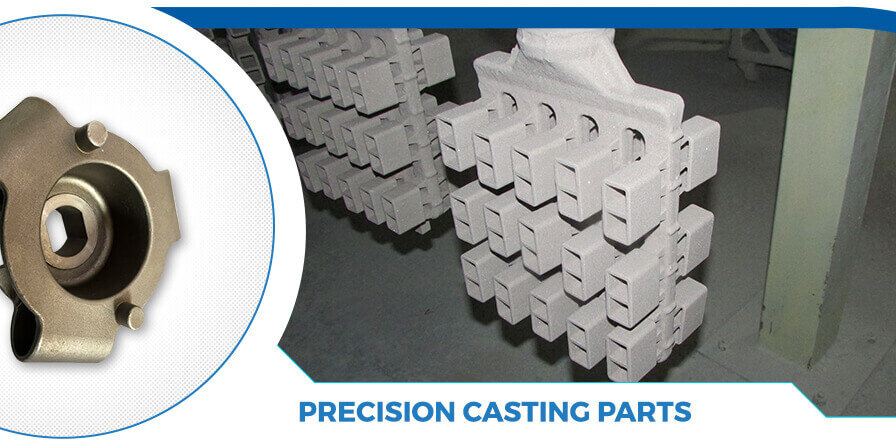

2. Shell Building

Shell making process is a whole silica sol process, namely dip the assembly into good colloidal silica coating, sprinkle with fire-resistant sand, dry and harden shell under certain temperature,thus to form dense refractory coating surface outside the surface of wax models, and then repeat the step 5-6, finally form a certain strength and refractoriness of silica sol shell.

3. Dewaxing

Dewaxing is a process in which the wax inside the shell is melted by high temperature steam and then drained out, resulting in a cavity that can be poured into the mold.

4. Pouring

Melt stainless steel ingots into liquid status under a certain high temperature, then pour the liquid into the shell and cool under room temperature. After solidification, knock out the blacks and clean sand.

5. Cutting,Grinding & Surface Finishing

Cut the stainless steel casting blanks from the assembly one by one, remove the sprue gate by grinding machine, and smooth the surface with various surface finishes, such as shot blasting, sandblasting, electropolishing, mirror polishing, etc.

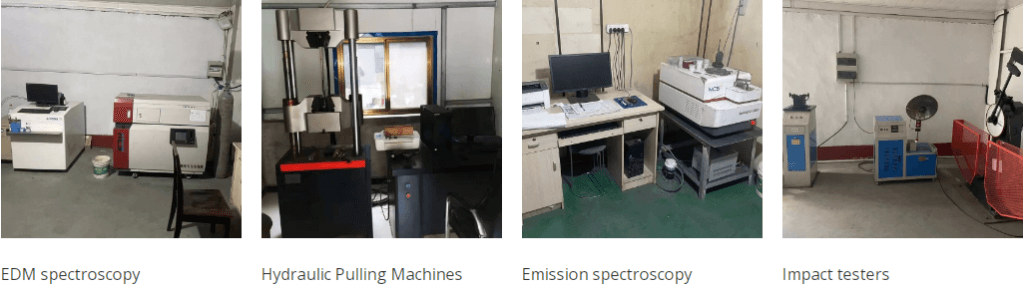

6. Inspection

After finishing production, inspection is also an indispensable process before delivery. The inspection of stainless steel castings includes dimensional inspection, defects inspection, and material inspection. Only qualified products can be shipped to customers.

You’ll get the most significant advantage from using investment castings if your part:

- has a complicated shape that would be difficult or impossible to produce with other casting methods

- requires exceptional surface qualities

- needs tight tolerances

- prefers minimal surface finishing or machining after casting.

- Affordable Tooling: Tooling is the basic step to starting the stainless steel casting process. Although the machining accuracy and material of tooling play an important role in the final casting quality, the tooling of stainless steel is relatively affordable compared with other forming processes.

- Flexible design: Investment casting can cast out stainless steel products in different sizes and weights, so the design of cast stainless steel parts is very flexible. Stainless steel casting allows parts with a minimum 3mm thickness and weights ranging from 0.05kgs-80kgs. Besides, stainless steel castings with complex structures are also castable.

- Close Tolerance: The dimensional accuracy of stainless steel investment casting can meet ISO 8062 CT5-CT6 level. Such close tolerance can ensure stainless steel castings with less or no machining.

- Good Surface: Even after shot blasting, the surface of stainless steel castings is very smooth and looks bright. And people will never worry about stainless steel castings will get rust with time flys.

- High Production Efficiency: Stainless steel casting is a fast and repeatable process, so the production efficiency is very high, and no matter it is a large or small volume, it can all meet.

Hengke Metal is one of the leading stainless steel investment casting companies in China. We can use our field spectrometer to help you find the right alloy for your stainless steel casting requirements.

Stainless Steel Foundry is one of the leading stainless steel precision casting companies in China. We can manufacture custom stainless steel investment castings to your exact design specifications. For parts from 50g to 50kg or larger, we offer tight tolerances and consistent part repeatability.

Our design and production capabilities include:

- Complex, near-net-shape parts without secondary machining

- Easily convert multiple parts into a single component

- Thin Walls to Reduce Weight

- Ra6.3 even better surface finish

- Linearity tolerance within CT4-CT6

- Highly complex solid geometry

- High-precision workability

Our proven casting technology makes us the most reliable one-stop supplier of stainless steel castings. The competitive price of stainless steel castings and a full range of services are the most attractive factors for foreign companies such as the United States, Britain, Canada, and Australia to purchase our products in China.

Need Stainless Steel Casting Services in China? Contact us now! hengkemetal@gmail.com