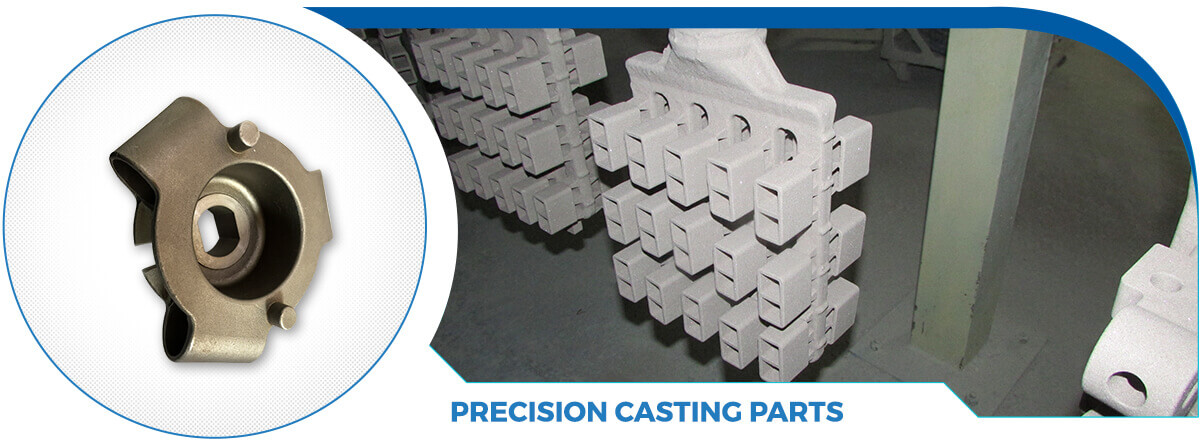

Precision Casting or Investment Casting

Precision casting or Investment Casting Precision casting is a general term for the process of obtaining accurate dimensional castings. Compared with the traditional sand casting process, precision casting obtains castings with more accurate dimensions and a better surface finish. It includes investment casting, ceramic casting, metal casting, pressure casting, and disappearing mold casting. Precision casting…

Details