Contents [hide]

The Complete Buying Guide: Basics of casting

Casting is one of the most used metal; fabrication processes in metalworking. The process involves setting molten metal in predesigned molds. Once the molten metal is left to solidify, it takes the shape of the mold. Casting can be achieved using veracious ferrous and non-ferrous metals and alloys.

In metal casting, alloys are used to define the shape and design of the finished item. Additionally, there are many metal casting processes. Every type is different in terms of mold used or material design. This guide will help you know more about the basics of casting.

Basics metal casting processes

Every metal casting process is unique. However, they revolve around the same principle. All the methods go through the same basic steps as shown below:

· Making the patterns

Before creating molds, casting manufacturers must design the patterns. The process of fabricating mold patterns is called pattern-making. This is mainly done using a computer-assisted design system. The process involves creating the mold’s dimensions and geometry, followed by packing materials around the pattern.

· Making cores (optional)

This is an optional process, depending on the `part you want to fabricate. Since many designs require a core, the manufacturer must place solid materials inside the mold cavity to create its interior surface.

· Molding

This phase involves mold creation. Various materials, such as sand, plaster, or wax, can be used to create molds.

· Mold filling

This stage involves pouring molten metal into the mold. The metal is then left to cool and solidify before the mold is broken to remove the finished part.

· Finishing

The fabricated metal part may have cracks and rough surfaces from the mold used. This depends on the type of casting used. In this case, you may need post-processes to give the components a more refined surface finish.

Types of Casting Processes

Metal casting is one of the most used and oldest metal fabrication methods in the world. However, recent advances in technology have led to the invention of many casting types. Accordingly, every process has its advantages and disadvantages. Here is a brief on different casting basics.

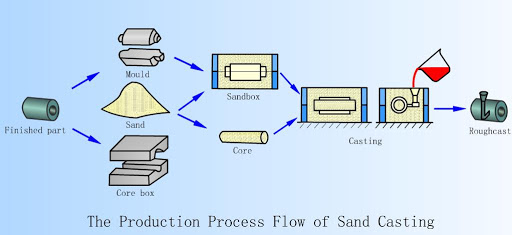

1. The Basics of Sand Casting

Sand casting is a metal casting technique that uses sand impacted with clay and other bonding agents to form molds. The casting process is designed to reduce cracking and other defects. This means more flexibility and reduced shrinkage.

After the mold is designed, molten metal; is poured and left to cool and solidify. After that, the mold is destroyed to remove the finished component. One of the benefits of sand casting is that the sand can be reused in making other molds. This lowers the overall cost of production.

However, sand casting produces metal components with rough surfaces and may need pos-treatments.

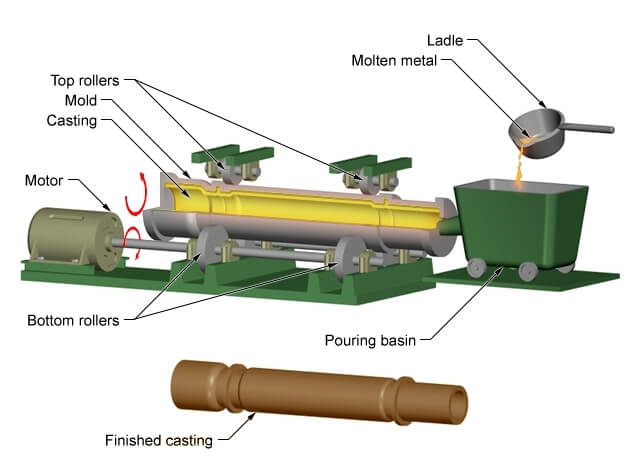

2. The Basics of Centrifugal Casting

The centrifugal casting process is different from all other casting techniques since it uses rotating molds. The process is known for its excellent quality and material soundness. Accordingly, it is one of the most basic casting methods.

Centrifugal casting is further divided into vertical centrifugal casting and horizontal centrifugal casting. The difference between these two is the direction in which the axis rotates.

When the mold is placed on an axis that rotates vertically, the process is vertical centrifugal casting. On the other hand, a mold that turns on a horizontal axis leads to horizontal centrifugal casting.

Centrifugal casting is suitable for the manufacture of components with thin walls and consistent diameter.

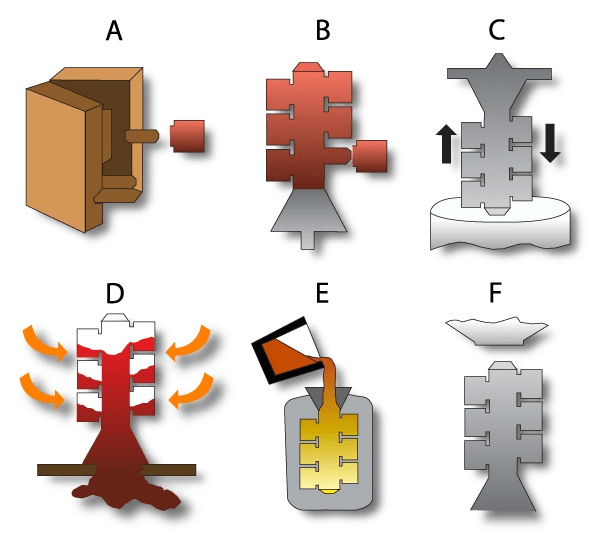

3. The Basics of Investment Casting

Investment casting is also called precision casting or lost-wax casting. The process is the best metal casting technique if you want components with an excellent surface finish.

The precision casting process involves the use of molds made of wax and coated with refractory materials. Like all other methods, the process involves pouring molten metal into the predesigned mold, leaving it to cool and solidify, before removing the mold to get the final product.

Since the process ensures a high degree of accuracy and surface finish, it may not require post-treatment. Additionally, investment casting is capable of producing metal parts with intricate shapes and designs. However, the process can be costly since it requires more labor and tooling.

As shown, every casting method has advantages and disadvantages. This means that you may want to look into each technique separately to determine the suitable one for your project.

The Benefits of Metal Casting

- Casting is one of the methods used in metal fabrication. Accordingly, there are many options you can look into depending on your project. With all the available techniques, here are the general advantages of metal casting:

- Casting has the ability to create intricate designs and shapes. This is essentially suitable for applications in the defense, aerospace, automotive, and medical industries.

- Accordingly, casting has shorter production cycles, enabling you to mass-produce various metal parts with little investment in tooling.

- With casting, you can achieve versatile surface textures.

- Casting can produce virtually parts of every size. There is minimal size limitation when it comes to casting metal components.

- With casting, you can manufacture the entire part at once. This reduces the need to assemble various components.

Factors to Consider When Casting

There are many factors you should consider when determining the type of casting to use. You have to ensure you manufacture products of high integrity and proper size and shape. Here are the things to keep in mind:

- Type of materials to use

- The material’s cooling rate

- Material’s shrinkage

- Desired surface finish

- Product’s features

These and other factors should help you choose between investment casting, sand casting, centrifugal casting, and die casting. Accordingly, you can opt for other metal fabrication techniques, such as forging, if metal casting is not practical.

The Bottom Line

Metal casting is a vital part of the engineering industry and has been applicable for ages. Accordingly, metal casting is considered a mass production technique used by various manufacturers to design and make intricate components.

Metal casting varies depending on the material and mold used. However, the process is generally economical regardless of the metal casting technique you use. This introductory guide should help understand more about metal casting processes. You should consider more research on individual metal casting processes if you want to more.