Contents

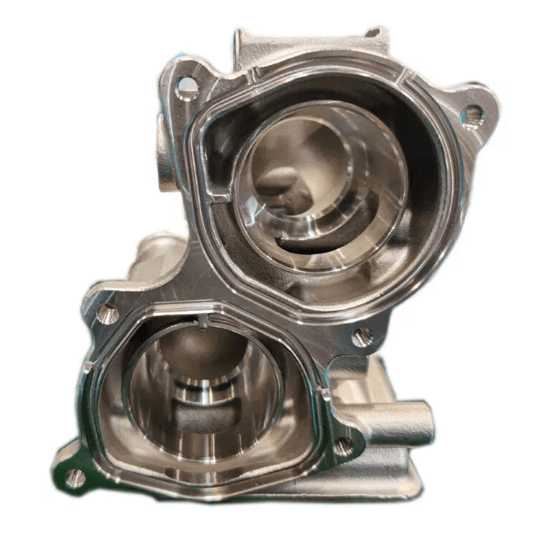

Stainless steel valve casting products

Stainless steel valve casting products mainly include: stainless steel gate valve castings, stainless steel ball valve castings, stainless steel globe valve castings, stainless steel butterfly valve castings, stainless steel check valve castings, stainless steel plug valve castings, stainless steel filter castings, stainless steel discharge valve castings, stainless steel plunger valves Castings, stainless steel trap castings, stainless steel control valve castings, etc.

Valve castings require highly complex designs and alloys. We are a special stainless steel investment casting manufacturer and supplier in China. We are experienced in the manufacture of different types of stainless steel valve castings.Stainless steel valve castings mainly include: 301, 304, 316, 304L, 316L. Or by international standards: CF8, CF3, CF8M, CF3M. The quality of the materials is upgrade in turn.

Valve castings are control components in pipeline fluid delivery systems for fluid control valves.Variety and specifications. Valve castings are widely used in chemical, petrochemical, petroleum, paper, mining, electric power, liquefied petroleum gas, food, pharmaceutical, water supply and drainage, municipal, mechanical equipment, electronics industry, urban construction and other fields.Today we mainly introduce our stainless steel valve castings:

Stainless Steel Valve body, Valve disc,Valve bonnet, Valve gland

Valve body: Investment casting valve body is the core part of whole vave and holds all valve components(valve disc,valve bonnet,ect) together. It is what regulator fluid flow through the transmission to determine which gear it goes into. They can be cleaned/rebuilt/replaced and it usually does not cost too much.

Product Basic Description

| Name | Precision silica sol investment casting 316 stainless steel valve body water pump |

| Material | Carbon steel, stainless steel, alloy steel, aluminum steel, or other materials |

| Standard | DIN, ASTM, BS, JIS etc. |

| Process | Sand casting,resin bonded casting, investment casting(lost wax casting), die casting, pressing & forging. According to customer’s detailed drawings or samples. |

| Surface treatment | Polishing, sand blast or according to customer’s requirements |

| Machining | Complete machining such as Machining center, CNC, Lathe, Milling machine,drilling etc. |

| Size and design | As per the customer’s drawings and requirements, samples |

| Packing | Seger normal export packaging or As per customers’ requirements |

| Inspection | Foundry in-house or Third Party inspection available upon customers requirements |

Valve disc: Investment casting valve disc is one of most common components, which is applied to butterfly valve.Investment casting valve disc is opening and closing of control medium flow and circulation, playing a vital role in the whole valve structure. It could be operated by valve handle,or through equipments like turbine operation,pneumatic,electric equipment.

Finished Product Basic Description

| Item | Butterfly valve disc |

| Materail | Stainless steel |

| Size | DN200 |

| Surface Treatment | Vacuum heat treatment |

| Application | Butterfly valve |

| Casting Process | Silica sol casting |

Valve bonnet: valve bonnet is a valve component with valve stem seal parts,used to connect or support actuators.Valve bonnet can be a whole with valve body,but also can be separated.There are two fuctions of valve bonnets,one is valve stem position to ensure stem drive switch normally.Another is sealing function,have a certain strength, preventing the internal fluid flow.

1 Valve bonnet Product Basic Description

| Product Name | investment casted stainless steel valve bonnet, valve cap |

| Item No | 30.1000.010.00 |

| Material | Stainless steel 304 (CF8) |

| Weight | 1-2 Kg |

| Major production process | Precision Investment casting |

| Surface treatment | ball blast |

| inspection method | dimension inspection+appearance inspection |

| Used | industry, valve,pumsystem, auto application |

Valve gland: Valve gland is one component of the valve assembly. The valve gland is used to cover the valve gate, worked as the sealing parts.

About the quality inspection,each valve casting made at our foundry is pressure tested. And often be put through non-destructive testing (NDT) to check the integrity of our products. We guarantee no leaking from any product we manufacture.Besides it, our silica sol casting process can result in a good surface finish and dimensional accuracy. So that we can meet the drawing requirement with casting only, and no machining will be operated. A combination of sand mixtures and a special washes are used on our valve castings for unparalleled finishes.

To be your Trusted Valve Casting Foundry partner in China

Our aim is to delivering quality stainless steel castings to our customers. Our facility and processes are designed to provide stainless steel valve casting components meeting every requirement listed. From our products to our customer service, they are all our working standard.

If your are looking for stainless steel casting products and services in China. Why not contact us freely. Maybe your request will be finished with satisfied services.