The Secrets of Investment Casting

Contents

What Is Investment Casting?

Investment casting is also known as the lost wax casting process or precision casting. This process involves the use of ceramic molds created with wax. The “investment” part comes from dipping the wax pattern in a ceramic slurry.

After this stage, the shell is heated to remove wax. The remaining shell is where molten metal is poured and left to solidify as it cools. This is followed by breaking the shell to reveal the final product.

Investment casting can be very complex. However, the process is cost-effective, precise, and offer smooth surface finishes.

Additionally, the investment casting process is mainly used in the aerospace and medical industries. This is primarily because investment casting allows investment casting manufacturers to produce parts with intricate designs and shapes using a wide variety of precision casting materials.

How Does Investment Casting Work?

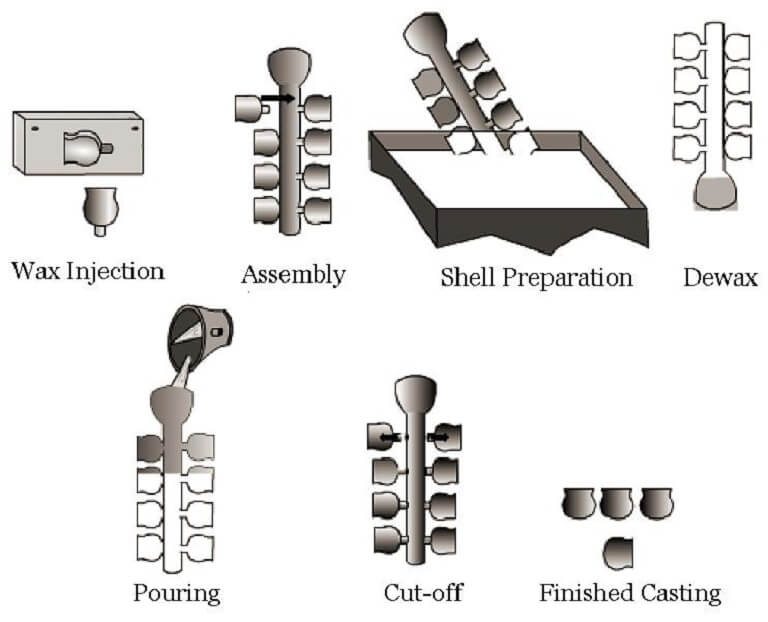

The investment casting process is always complex and may require training with various equipment. The entire process follows these steps:

· Creating wax pattern

During this stage, investment casting manufacturers use similar details from the finished part to design wax patterns. However, an allowance is maintained to cater for shrinkage. These patterns are made of wax, which is injected using a die.

· Assembling the tree

Once the wax pattern is created, it is assembled with other wax components to produce a gating system to deliver the molten metal into the mold.

Many wax patterns can be assembled to make a tree.

· Creating the mold shell

The assembled wax pattern is dipped in a ceramic slurry to strengthen it. This process is repeated until the desired thickness is achieved.

The mold shell is then allowed to dry, making it even stronger.

· Dewaxing

After the mold shell has dried, it is heated in a process known as dewaxing to melt away the wax. The ceramic mold remains with a cavity through which molten metal is poured. The cavity often has the desired shape and size of the finished part.

The heating effect during the dewaxing phase also increases the stability and strength of the ceramic mold, allowing it to retain molten metal until solidification is complete. Additionally, this process minimizes the reaction of the shell and the molten metal to reduce casting defects.

· Metal and cast

The ceramic mold is preheated until it reaches a specific temperature. Next, the molten metal is poured into the molds using the gating system.

It is worth noting that investment casting is very versatile and can be used to make parts with intricate designs from a wide range of ferrous and non-ferrous metals and metal alloys.

Air melting or vacuum melting may be used during this stage, depending on the type of investment casting material used. Vacuum melting is preferred when the investment casting material is highly reactive.

· Finishing

Once the part has cooled enough and solidified, the mold is broken to reveal the finished piece in a process called the knockout operation.

During this stage, the gates and runners are detached from the casting. Post-processes may be used to achieve the desired specification. However, it is worth noting that the investment casting process is very precise and offers an excellent surface finish. This feature reduces the need for machining and other final post-processes.

Additionally, the mold material is usually reused in the subsequent production cycles, making precision casting a cost-effective casting technique.

After the final operations, the part may be subjected to further testing for quality. For instance, the investment casting company may subject its products to dimensional inspections and non-destructive testing.

Benefits of Investment Casting

The secrets of investment casting lie at different stages of the casting process. These aspects make the difference when it comes to attaining the desired specification. They also make investment casting one of the best casting techniques to use. The benefits of the precision casting process include:

· Smooth surface finish

Investment casting foundries use ceramic molds, which produce excellent surface finishes. Typically, this aspect eliminates the need for machining and other post-processes.

· Faster production

Lost wax casting reduces labor time for quicker lead times. This is mainly achieved because the investment casting process eliminates the need for machining.

· Tight tolerances

Investment casting can achieve tight tolerance, reducing the need for machining.

· Cost-effective

The process is relatively cost-effective since it requires less expensive equipment compared to die casting.

· Variety of materials

Investment casting can be a very versatile casting method because it allows investment casting foundries to use a wide variety of materials. With investment casting, you can use many ferrous and non-ferrous metals and metal alloys, such as stainless steel, steel alloys, copper-based alloys, aluminum alloys, carbon steel, etc.

· Wide range of sizes

Investment casting allows precision casting manufacturers to produce both small and large metal components.

Factors to Consider When Using Investment Casting

There are many reasons to choose investment casting. Apart from its benefits, here are the factors that should help you determine if investment casting is suitable for your project:

· Tooling cost

Investment casting can be very costly if you want to produce parts in low volume. Therefore, for low quantity requirements, you may want to opt for SLA or printed patterns as cost-effective alternatives.

Additionally, you will want to look into the initial cost of production. This involves the cost of purchasing new equipment and materials. In this case, the price can be very high. You will have to weigh the costs if you want to invest in investment casting.

· Size limitations

Investment casting can achieve different size ranges. However, it is hard to produce parts that are smaller than 1.6mm or deeper 1.5 times in diameter.

· Timing

The investment casting process is very complex, and the stages may be time-consuming. You should consider this factor if you need investment casting parts delivered within tight deadlines.

The Bottom Line

Generally, investment casting is a very effective method of metal fabrication. This aspect makes it a widely used process in different industries. The many benefits of investment casting enable manufacturers to produce parts with intricate designs for the aerospace, medical, automotive, oil and gas, and agricultural industries.

As mentioned, the secrets of investment casting lie in different stages of the casting process. You may want to look into every casting aspect to determine if investment casting is suitable for you.