Investment Casting Vs. Lost Wax

Investment casting and low wax casting are two terms that are usually used interchangeably to refer to a metal casting process. However, the two processes have notable differences that any casting foundry should know.

This article outlines the differences between investment casting and lost wax casting processes.

Contents

Investment Casting vs. Lost Wax Casting

Modern-day investment casting, also called precision casting is a very versatile casting technique. It is capable of achieving accurate parts with tight tolerances, thin walls, and excellent surface finishes.

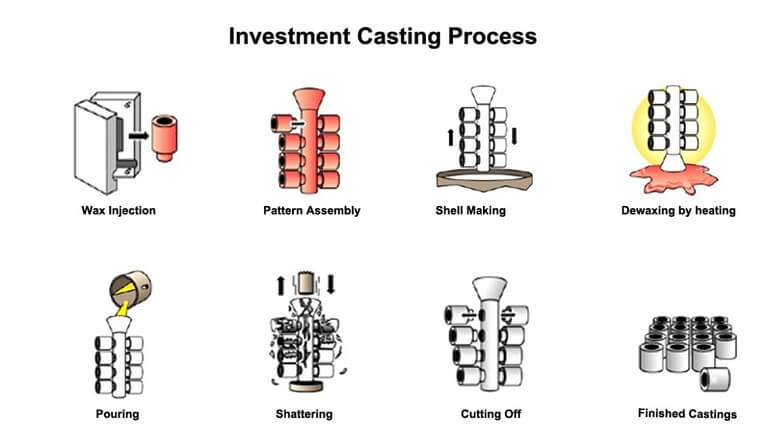

The investment casting process involves creating a wax pattern by dipping it in a ceramic slurry. This process offers superior dimensional accuracy while eliminating the need for machining and other post-processes.

On the other hand, the lost wax casting process is relatively accurate. The history of the lost casting process involved the use of molds made of beeswax and clay. This aspect made lost wax casting suitable for making products, such as ornaments and jewelry.

Initially, the term investment casting came into use in the 1940s since the pattern used was designed for an investment compound. Unlike the traditional lost wax casting, investment casting is capable of producing parts that can withstand high temperatures and tight tolerances.

The Differences between Investment Casting and Lost Wax Casting

The lost wax casting process dates back to ancient times. The process involved the manufacture of metal sculptures from original casts. The most common lost wax casting materials included silver, brass, gold, and bronze.

Currently, casting foundries use investment casting for the industrial manufacture of various metal components that require tight tolerance, smooth surface finish, and dimensional accuracy. Although the modern casting method is called investment casting, some manufacturers still call the lost wax casting process.

The difference between these processes is usually seen in the mold creation process. For instance, lost wax casting used beeswax to create mold, which was later destroyed to reveal the final piece.

In investment casting, more complex tools are used for superior accuracy. Additionally, modern investment casting uses advanced wax material and alloys to create patterns. Accordingly, the mold materials can be reused for other production cycles. This minimizes waste and production costs.

However, both lost wax casting and investment casting require wax that is resilient enough o without pressure and force experienced during the casting process.

Investment casting is widely applied in many industries today. This is mainly due to its ability to produce parts with smooth surface finishes and dimensional accuracy. Additionally, the process is very cost-effective because it does not require machining or other post-processes. Investment casting also offers great flexibility due to a wide range of materials that can be used to produce different parts.

Due to advanced technologies, investment casting has become a better and more efficient casting method than the lost wax casting process. Modern investment casting offers a cost-effective method of metal fabrication with reduced production cycles due to fast prototyping.

As mentioned earlier, there is a thin line between investment casting and lost wax casting. The main differences between investment casting and lost wax casting can be listed as follows:

- During the lost wax process, molds are manually made separately. On the other hand, investment casting uses complex processes to create wax patterns.

- Lost wax casting is suitable for the manufacture of metal parts of smaller sizes, such as jewelry and ornaments. On the other hand, investment casting is most suitable for manufacturing more complex parts.

- During the lost wax casting process, one wax pattern can be used to make other patterns, while in investment casting, it is possible to produce a replica of the desired part.

- During the lost wax casting process, the main focus is on the wax or mold used. On the other hand, in investment casting, the attention is usually put on investment casting materials.

What Is Lost Wax Investment Casting?

The lost wax investment casting process is a metal fabrication method that uses wax patterns to create molds. Molten metal is then poured into the mold and left to solidify before the shell is destroyed to obtain the final piece.

Why Investment Casting Is Called Lost Wax Process?

The investment casting process is a metal fabrication process based on the traditional lost wax process. However, the term lost wax casting is nowadays used to mean investment casting.

Investment casting is an age-old casting method. Investment casting is also called the lost wax casting process because it invests the wax pattern with a refractory material, usually a ceramic slurry, to create molds.

The investment casting process is a versatile method that cast materials, such as stainless steel. Steel alloys, aluminum alloys, superalloys, copper-based alloys, and many other materials.

Lost Wax Investment Casting Products

The lost wax investment casting process is used in many industries due to its reliability and high precision. The process has been used to manufacture different investment casting parts using a wide range of ferrous and non-ferrous metals and metal alloys.

Investment casting applications are essential in the aerospace, automotive, military, medical, and oil and gas industries.

Lost wax investment casting parts include:

- Engine turbines

- Blades

- Hydraulic fluids systems

- Brake systems

- Engine components in the automotive industry

- Gearboxes

Advanced casting technologies and other modernizations in 3D printing ensure superior part quality and faster production cycles.

Lost Wax Investment Casting Materials

Investment casting materials are many. This is mainly because the process is versatile. Examples of well-known investment casting materials include:

- Stainless steel

- Steel alloys

- Aluminum alloys

- Copper-based alloys

- Titanium alloys

- Cast iron

- Carbon steel, etc

The Bottom Line

As mentioned, investment casting and lost wax casting are two terms that have been interchangeably to refer to a process of metal fabrication. However, it is worth noting that the two methods have differences that set them apart.

For instance, the lost wax casting is the oldest of the two methods.

In the lost wax casting, molds were initially made of beeswax and clay. On the other hand, investment casting is the modern version of the lost wax casting process. The investment casting is more advanced and uses advanced wax for mold creation. Other notable differences between the investment casting process and the lost wax casting process are seen in the stages of production and the properties of the final piece.