Buying Guide: Investment Casting Manufacturer

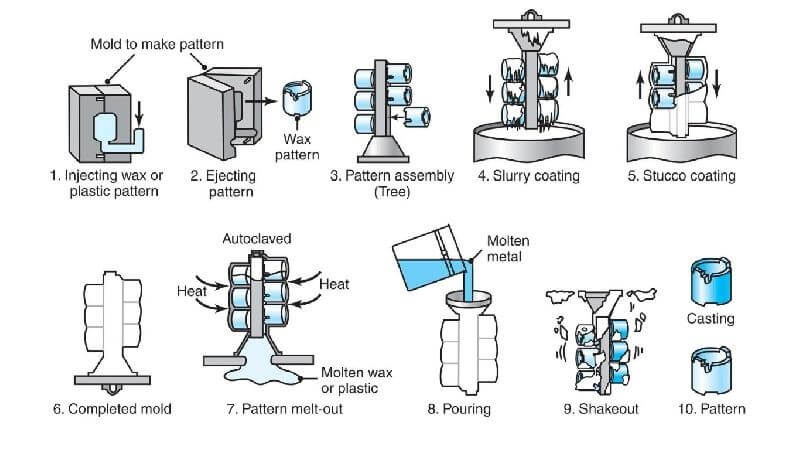

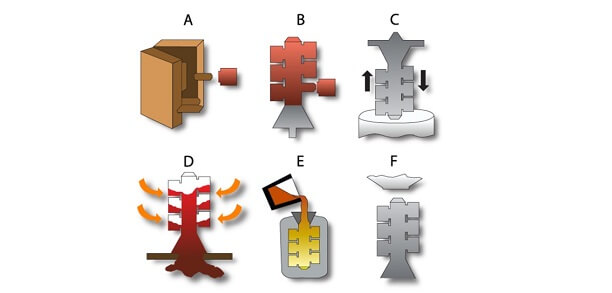

Investment casting is one of the most used metal fabrication techniques. The process remains the best in terms of surface finish and dimensional accuracy. Therefore, precision casting is used in many applications and industries alike.

Companies that produce precision casting products are called investment casting foundries, investment casting suppliers, or investment casting manufacturers. These facilities are known to manufacture high-quality parts using a wide range of materials. Accordingly, this article will help you know more about investment casting manufacturers.

Contents

Choosing an investment casting manufacturer

Choosing an investment casting company may not be as straightforward as choosing the best product. Metal casting is a process that requires a lot of considerations. For instance, you need to determine if the investment casting foundry is certified before striking a deal.

Generally, your responsibility should be to find the most qualified and responsive precision casting company. In some cases, most buyers assume that as long as the investment casting supplier is willing to meet contractual needs, that is all required. However, this can be a costly mistake in the long run.

Factors to consider when choosing the right investment casting manufacturer

Have you ever worked with an investment casting foundry or visited their facilities? If yes, then you know how complex and manually intense the processes can get.

The investment casting process is the most time-consuming of all the casting methods. Therefore, you need to take your time when looking for an investment casting manufacturer. Here are things you should consider to help you go through the processes effortlessly.

1. Quality and value

When selecting the right precision casting company, you need to consider the quality of products against prices. This way, you should know if what you are getting offers value for money or not.

You need to audit the manufacturing processes and materials used. Additionally, you need to determine your minimum requirement. If you want the most affordable lost wax manufacturer, be sure to compare different foundries. The same should apply when quality and service are your utmost requirements.

2. Company certification

Most investment casting applications require certifications. This means that the investment casting supplier must meet all quality and safety requirements and standards. Therefore, you should confirm if your dealer has the right documents and uses the required processes. This should be an overwhelming task since most foundries list their certifications on company websites.

Accordingly, you may need testing to determine if the products meet your required specifications. Some manufacturers may offer in-house testing to make your work more manageable.

3. Production capabilities

Depending on the products you need, you may want to look into an investment casting foundry’s ability to meet your requirements in terms of volume. For instance, your business may need continuous supplies that require the manufacturer to mass-produce what you need.

To make it easier on your part, you should consider letting the investment casting supplier know what you need. You can also include your deadlines.

4. Delivery speed

When you think about investment casting, the first thing that comes to mind is the production cycle. The entire process can be slow. However, are your projects ready to wait? If not, you need to find a manufacturer capable of meeting your deadlines.

Speed of delivery is crucial for your business. For instance, if the shipped part is defective, you need time to return it and get a better replacement. If the supplier cannot deliver in time, this aspect alone can get your clients waiting, which is not good for business.

5. After-sale support

Another essential consideration is after-sale support. Investment casting can have its defects. Accordingly, when things go south, you may not be able to rectify them by yourself. Therefore, you need a responsive precision casting supplier.

Additionally, you should ask if the manufacturer offers assistance in installations, maintenance, and repair. This is significantly beneficial with delicate parts that require technical expertise. The best investment casting foundry should offer after-sale support to make your work more manageable. Additionally, a supplier that helps you cut costs by providing free delivery is the best.

6. Visit the foundry

The best way to determine if the investment casting supplier is right for your business is by taking a physical tour of the manufacturing facility.

Most precision casting companies invite prospective clients to foundry tours. This should be an opportunity to understand their processes and operations. Additionally, the chance to visit an investment casting company should help you better understand the manufacturer and ask questions you may have. Here are some questions you should ask to ensure you determine if the supplier meets your requirements and expectations?

- Can you produce and supply X volume by X date?

- Which after-sale services do you offer?

- How long do I have to wait for you to fulfill my order?

- Do you accept defective products back?

- Which processes do you use to minimize casting defects?

- What percentage of defects do you experience after a complete production cycle?

- How many clients do you supply with the same products?

- Are you certified?

- What is your product list?

- Do you also use other types of casting?

By the end of this tour, you should have all the information you need to make an informed decision about the supplier.

It is essential to create a positive relationship with an investment casting supplier. At this stage, you should know the manufacturer you want to work with. It will help if you agree on what you expect from each other. Additionally, you may want to draw a contract that captures every party’s terms and obligations. In case of a dispute, you should find the most amicable way to solve it.

The Bottom Line

Many people think about investment casting as a product. However, the entire process is very complex and time-consuming. Therefore, choosing the proper investment casting manufacturer can be a bit daunting, which means you have to be very attentive when doing it. You should make an exhaustive audit of the supplier and his processes to see if he meets your requirements.

The investment casting company’s website should be an excellent place to start. Look at its product portfolio and certifications. Reviews should also help you determine a supplier’s reputation. Lastly, use this article for a more comprehensive audit to find the best investment casting manufacturer for you.