Contents

The Complete Buying Guide: Auto Casting Parts

There is a compelling need for automobile parts manufacturers to make strong yet lighter parts that can work well and withstand harsh conditions. Hence, many casting automotive manufacturers are taking casting methods to produce these parts. Note, different casting methods are used to make this parts. But the choice depends on the quality, design, complexity, and precision needed on the parts.

What are Auto Casting Parts?

These are automotive parts that are produced using different casting and forging methods. As a result, such components are lighter, stronger and they have superior corrosion performance.

Besides, the auto casting parts have become more competitive, complex, and highly geometrical with different shapes and sizes. Moreover, the need to have dimensional accuracy and large volume production of the casting auto parts has pushed automotive producers to apply high technology and innovation in automobile parts made by casting.

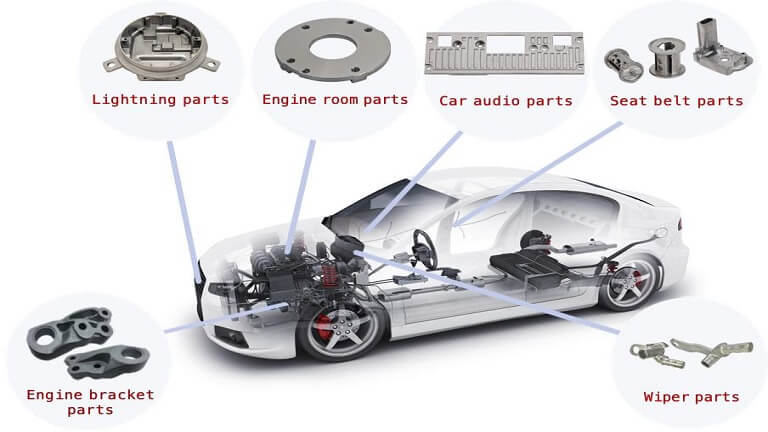

Casting in automobile industry has numerous applications in casting components such as:

- Transmission components

- Vehicle interior components

- Engine blocks

- Wheels

- Wheel spacers

- Carburetors’

- Shift forks

- Drum gear

- Vehicle chassis.

These casting auto parts require different casting methods depending on the complexity of the automotive casting parts being made. The automobile parts casting methods and material used include the following.

Methods

- Die casting

- Sand casting

- Investment casting

- Pressure die casting

- Gravity Die casting.

Materials

- Aluminum

- Zinc

- Carbon steel

- Stainless steel

- Magnesium alloys

- Titanium

- Grey iron and ductile iron

- Ferrous and non-ferrous materials

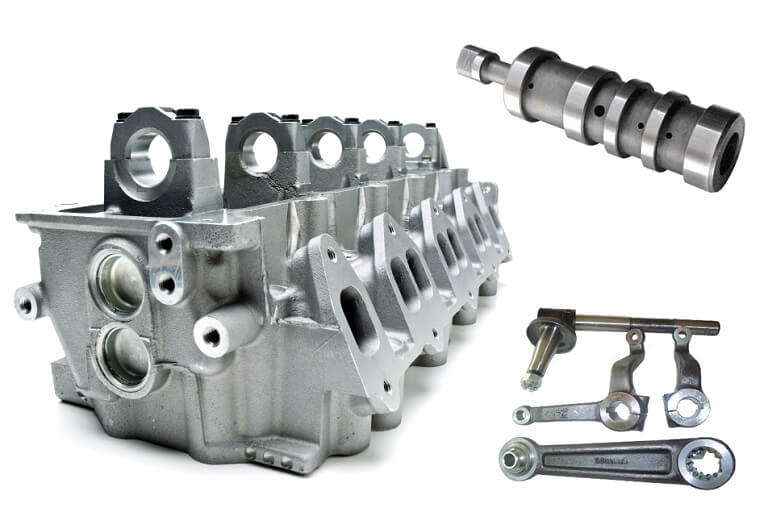

Cast iron Automobile parts

Casting auto parts using cast iron works well in casting automotive parts. The cast iron auto spare parts casting has a relatively low melting point and has excellent resistance to wear and tear, and good machinability with high fluidity levels.

Therefore, casting auto parts such as

- pistons,

- cylinder heads,

- crankshafts,

- engine blocks

All the above parts are cast iron products.

Moreover, casting metals such as Gray cast iron, white cast iron, ductile cast iron, and malleable cast iron works well with the die casting method. Because of its strength and manageable costs

However, the choice and the type of iron cast will depend on the automobile casting parts. But the preferred cast iron by casting manufactures is the gray iron.

Aluminum Die Casting Auto Parts

Aluminum material is primarily used for die casting in the automotive industry across the world. The aluminum die casting auto parts perform well like the cast iron. However, these automobile parts made by casting are relatively cheaper as compared to other metals.

Also, aluminum is equally strong, durable, and flexible to work with. It can withstand high temperatures, wear and tear. But the good news is that the aluminum die casting auto parts are lighter than the cast iron automobile parts.

Different casting methods such as sand casting, investment casting, and mold casting can work with this aluminum casting material. However, die casting is most popular with aluminum because it is an efficient method that adds strength and durability when combined with other metal alloys.

There are different aluminum die casting auto parts such as

- Engine block,

- Cylinder head,

- Gearbox,

- Wheels and

- Vehicle chassis.

All these automobile parts form a bigger junk of the large and global automotive parts aluminum die casting market. Therefore, the India automotive parts aluminum die casting market is one place that needs the supply of aluminum die casting auto parts.

Investment Casting Automotive Parts

The investment casting method is used by manufactures who need automobile parts with an excellent surface finish, high tolerance, strict dimensional accuracy, and complex shape with thin walls.

It is a reliable method because

- It gives manufacturers the choice of design, material and allows them to adopt new design shapes.

- Investment Casting automotive partsminimize material wastage, thus cutting costs on expensive metal alloys

- Investment casting for automotive partseliminates part machining and thus lowers the cost of production

No wonder metal alloys such as copper alloys, carbon steel alloys, aluminum alloys, unique alloys, and other materials work in casting auto parts using investment casting techniques.

Therefore, investments casting automotive parts are unique in the automotive casting industry. Parts such as

- Shifting forks

- Stainless steel flywheel

- Carbon steel rocker arm shaft

- Rocker arms shaft.

- Transmission part

- Intake manifolds

Best of all, you can have your casting automobile part customized depending on your materials and the investment casting method of your choice. For example, if you choose to have auto parts steel castings, precision lost wax investment casting techniques make it easier for steel metal to be worked on.

Automotive Parts Magnesium Die Casting

Different die-casting techniques and methods are used to produce automotive auto parts cast by using magnesium metal alloy.

The casting methods depend on the type of auto parts. Those components require auto parts precision casting, vacuum die casting, gravity die casting, and pressure die casting.

Because of the technological advancement and application, the automotive parts magnesium die casting market, the die casting in the automotive industry manufactures prefer magnesium alloy compared to steel, aluminum, and cast iron.

Moreover, in comparison with other die casting auto parts, the automotive casting parts made by magnesium are

- Lighter and reduces the weight of other automobile casting parts

- When combined with other metal alloys, magnesium is equally more robust and durable

- Reduces air pollution because it boosts fuel consumption because of lightweight vehicle parts.

As if that is not all, automotive parts magnesium die casting market parts have continuously adapted magnesium, especially in the automotive parts die casting market Mordor.

Nonetheless, different casting parts name include

- Structural body

- Engine parts

- Gearbox covers

- IP beams

- Steering columns

- Fuel tank covers.

Conclusion

The automobile parts made by casting have continued to gain appearance in the automotive industry. Moreover, the need to have lightweight automobiles has made manufacturers adopt cast iron automobile parts to maintain a competitive edge.

We supply die casting auto parts such as aluminum die casting auto parts and automobile parts made by casting using other metal alloys such as ductile iron, gray iron, and steel casting auto products. Moreover, our investment casting automotive parts feature in the global automotive parts aluminum die casting market.